Hits: 32 img

In the paper processing industry, the

application of anti-adhesives is crucial. It is not only related to the

production efficiency and use effect of paper, but also directly affects the

economic benefits and market competitiveness of enterprises. Recently, a new

type of silicone material called Dimethiconol is gradually emerging in the

field of paper anti-adhesives, and has become the focus of industry attention

with its excellent performance and wide application prospects.

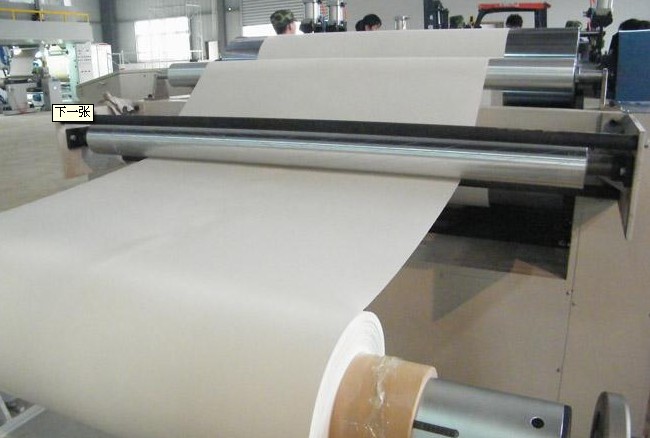

Dimethiconol is a silicone material polymerized from siloxane monomers, and the hydroxyl groups in its molecular structure give it higher reactivity. In the field of paper anti-adhesives, medium and high viscosity Dimethiconol is used as a base glue, and its cured film has excellent anti-adhesive effect. Whether it is label backing paper, asphalt packaging paper, or sealing paper tape backing paper, decorative paper backing paper, good anti-adhesive treatment can be achieved through this material.

Compared with traditional anti-adhesive materials, Dimethiconol has many advantages. First of all, its cured film has good weather resistance and chemical resistance, and can maintain a stable anti-adhesive effect in various harsh environments. Secondly, the use of this material can significantly reduce the production cost of paper and improve production efficiency. Finally, Dimethiconol alcohol also has good environmental performance, which meets the requirements of modern industry for green and sustainable development.

In practical applications, the use of Dimethiconol alcohol is also very convenient. Just dilute the material and apply it on the surface of the paper, and then cure it at room temperature or heat to form a stable anti-adhesive film. This simple production process not only reduces the production cost of the enterprise, but also improves the market competitiveness of the product.

However, despite the many advantages of Dimethiconol alcohol, some matters still need to be paid attention to during use. For example, the material cannot be mixed with acidic and alkaline substances, otherwise it may cause curing and viscosity changes. Therefore, during storage and transportation, ensure that the material is in a closed and clean environment to avoid contact with strong acid and strong alkali substances.

With the continuous development of the

paper processing industry, the requirements for anti-adhesive materials are

getting higher and higher. As a new high-performance material, Dimethiconol

alcohol is becoming an innovative force in the field of paper anti-adhesive

agents with its excellent performance and broad application prospects. In the

future, with the continuous advancement of science and technology and the

sustainable development of industry, the application areas of this material

will continue to expand, bringing more innovations and changes to the paper

processing industry.

More information please check: https://www.linkedin.com/posts/ariel-young-siliconeoil_dimethiconol-ohpolymer-hydroxylsilicone-activity-7293264037650345987-K9Us?utm_source=share&utm_medium=member_desktop