Hits: 12 img

In the United States, octamethyltrisiloxane is regulated under the Toxic Substances Control Act (TSCA). According to TSCA, manufacturers must conduct comprehensive assessments of MDM's toxicity, environmental behavior, and exposure risks, and submit relevant data to the Environmental Protection Agency (EPA). Furthermore, the EPA's Chemical Data Reporting (CDR) Rule requires companies to periodically report the production volume, usage, and exposure information of MDM.

In the European Union, octamethyltrisiloxane is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers must submit a registration dossier for MDM, including its physicochemical properties, toxicological data, ecotoxicological data, and risk assessment reports. Additionally, the EU's Classification, Labelling, and Packaging (CLP) Regulation mandates that companies correctly classify and label MDM to ensure its safe use.

In the cosmetics industry, the use of octamethyltrisiloxane is strictly regulated by the "Cosmetic Safety Technical Specifications." According to these specifications, the concentration of MDM in cosmetics must not exceed certain limits to ensure its safety for human skin and eyes. Cosmetic companies are also required to conduct skin irritation, sensitization, and phototoxicity tests to verify the safety of MDM.

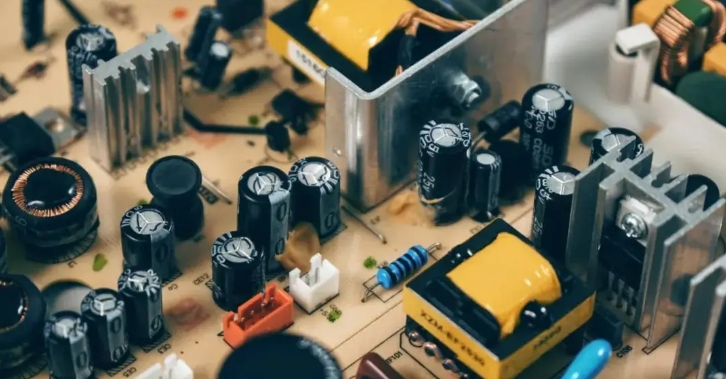

In the electronics industry, the use of octamethyltrisiloxane must comply with the Electronic Industry Citizenship Coalition (EICC) guidelines. These guidelines require companies to assess the environmental and social responsibility of MDM production and use, ensuring compliance with sustainable development requirements. Additionally, electronics manufacturers must strictly control the purity and impurity content of MDM to ensure its high performance in semiconductors and liquid crystal displays.

In terms of environmental protection, the production and use of octamethyltrisiloxane must adhere to the Strategic Approach to International Chemicals Management (SAICM). This approach aims to reduce the hazards of chemicals to the environment and human health, promoting sustainable chemical management. Many countries and regions have also established emission standards for MDM, requiring companies to effectively treat wastewater, exhaust gas, and solid waste to minimize environmental pollution.

The increasingly stringent global regulations on chemical management require manufacturers of octamethyltrisiloxane to enhance compliance in production. This includes improving production processes, optimizing wastewater treatment technologies, reducing exhaust emissions, and strengthening employee safety training. By ensuring compliance, companies can not only reduce legal risks but also enhance the market competitiveness of their products.

Regulatory pressures have also driven technological innovation in the production of octamethyltrisiloxane. For example, many companies have adopted green chemistry processes and nanocatalysis technologies to reduce environmental pollution during production. Additionally, some companies are developing eco-friendly alternatives to meet the market demand for sustainable chemicals.

To access global markets, the production and sale of octamethyltrisiloxane must comply with the regulations of different countries and regions. Companies need to understand the regulatory requirements of target markets and ensure their products meet relevant standards. For instance, in the EU market, companies must obtain REACH registration numbers, while in the US market, they must submit TSCA documentation. By meeting these requirements, companies can gain market access and expand their market share.

In the future, as global chemical management continues to strengthen, the regulatory requirements and industry standards for octamethyltrisiloxane will become even stricter. Companies must focus on technological innovation and compliance to address the challenges posed by regulatory changes. At the same time, with increasing environmental awareness, the demand for eco-friendly organosilicon compounds will grow, providing new opportunities for the sustainable development of MDM.

In summary, regulatory management and industry standards play a vital role in ensuring the safety and sustainability of octamethyltrisiloxane. Companies must actively respond to regulatory changes, strengthen technological innovation, and expand their markets to achieve sustainable development.

More information, please check: https://www.tiktok.com/@iotaariel/video/7470420878753418542